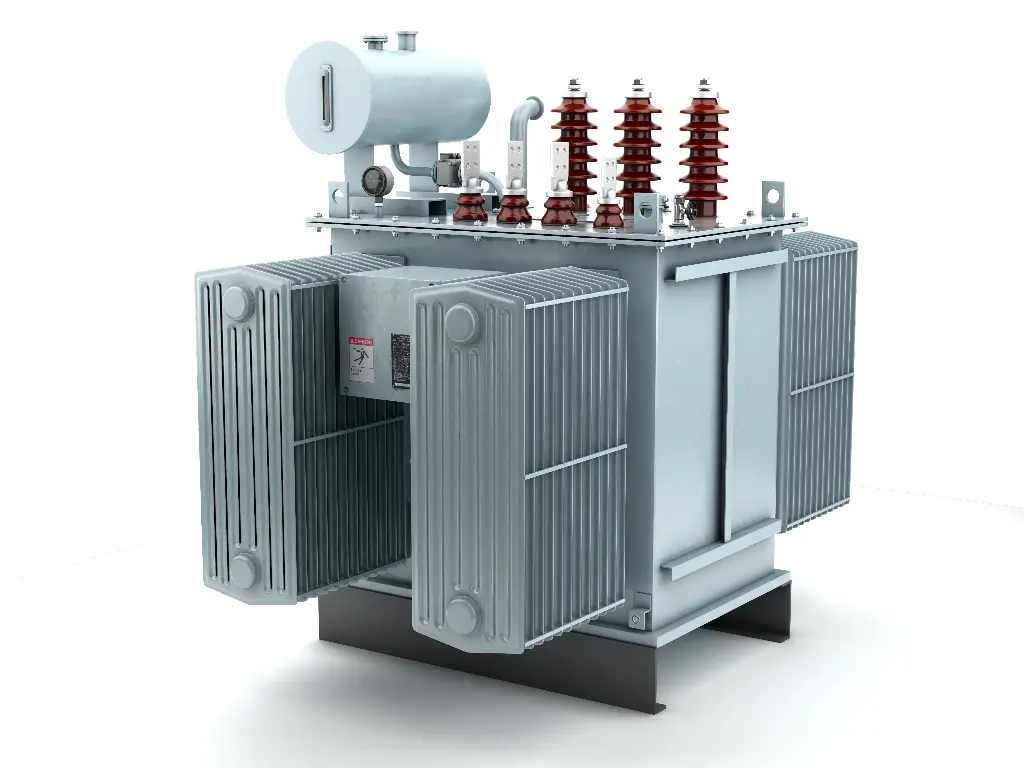

Power Transformer

• “Fire‑safe indoor transformers for data centers, metros, hospitals, and commercial towers — up to 33 kV.”

• “Cast‑resin dry‑type transformers: low maintenance, low smoke, high reliability for critical infrastructure.”

• “Designed to IS/IEC 60076‑11 with PD ≤ 10 pC, AN/AF cooling, and IP‑rated enclosures.”

| Specifications | |

| Type | Dry Type (VPI/CRT)/ Oil Cooled |

| Voltage Rating | Up to 33KV |

| Power Rating | 10KVA to 2.5MVA |

| Insulation Class | F Class for dry type (H Class on request) A Class for Oil Cooled |

| Cooling | AN/AF/ONAN/ONAF |

| Applicable Standards | IEC 60076, IS 2026 |

| Certifications | CE, ROHS |

Dry-type (Cast-Resin / VPI)

- Commercial & public buildings: malls, hospitals, airports, hotels, high-rises (indoor rooms, low fire load).

- Data centers & IT campuses: UPS/inverter isolation, LV/MV step-down near white space.

- Industries (indoor zones): pharma, food, beverages, textiles, electronics/semiconductor, cleanrooms.

- Transport infrastructure: metro/rail stations, tunnels, underground facilities (E2/C2/F1 focus).

- Education & healthcare campuses: labs, imaging suites, research buildings.

- OEM/machine integration: inside large machinery skids, test benches, E-house containers.

- Sensitive environments: museums, theaters, studios (low noise, no oil containment).

- Marine onshore facilities: cruise terminals, shipyards (indoor substations).

Oil-immersed (Mineral or Natural-Ester)

- Heavy industry: steel/cement/paper/sugar/chemicals—plant step-down, process substations, outdoor duty.

- Generation & microgrids: plant auxiliaries in thermal, hydro, captive cogeneration

- DG sets step-up/aux.

- Renewables (plant side): solar/wind inverter step-up, collector transformers, pad-mount/skid units.

- Oil & gas / petrochemical: refineries, tank farms, pipelines, FPSO topside auxiliaries (often ester for fire safety).

- Mines & minerals: pit-head substations, long cable feeders, harsh outdoor environments.

- Ports & airports (airside): apron lighting, shore-power, cranes/RTGs.

- Water & wastewater: treatment plants, desalination (outdoor/corrosive atmospheres).

- Traction & rail yards: depot substations, aux supplies.

- Agro/irrigation & remote sites: pump stations, farm/process clusters.

Dry Type Transformers -Myths vs Facts

• “Dry‑type can’t handle humidity.” — Fact: cast‑resin with proper IP enclosure works well in high humidity; sealing & heaters help in standby sites.

• “They’re always noisier than oil‑filled.” — Fact: modern designs meet low‑noise specs; AF mode can be the limiter — verify dB(A) at 1 m.

• “Maintenance‑free.” — Fact: no oil work, but you still inspect, clean vents, check fans/terminals, and trend PD/thermal health.

Selection Quick‑Help

• Define the space: room size, ventilation, access routes, floor loading; pick enclosure & IP early.

• Confirm duty: continuous vs cyclic, overload profile, ambient; decide AN vs AF and temperature class (F/H).

• EMC & harmonics: declare %THD and presence of large VFDs; choose K‑factor or isolation with electrostatic screen.

• Fire & codes: confirm local approvals; low smoke/halogen‑free preference for airports/hospitals/tunnels.

• Serviceability: specify space for coil inspection, fan replacement, and terminal access (front/top).