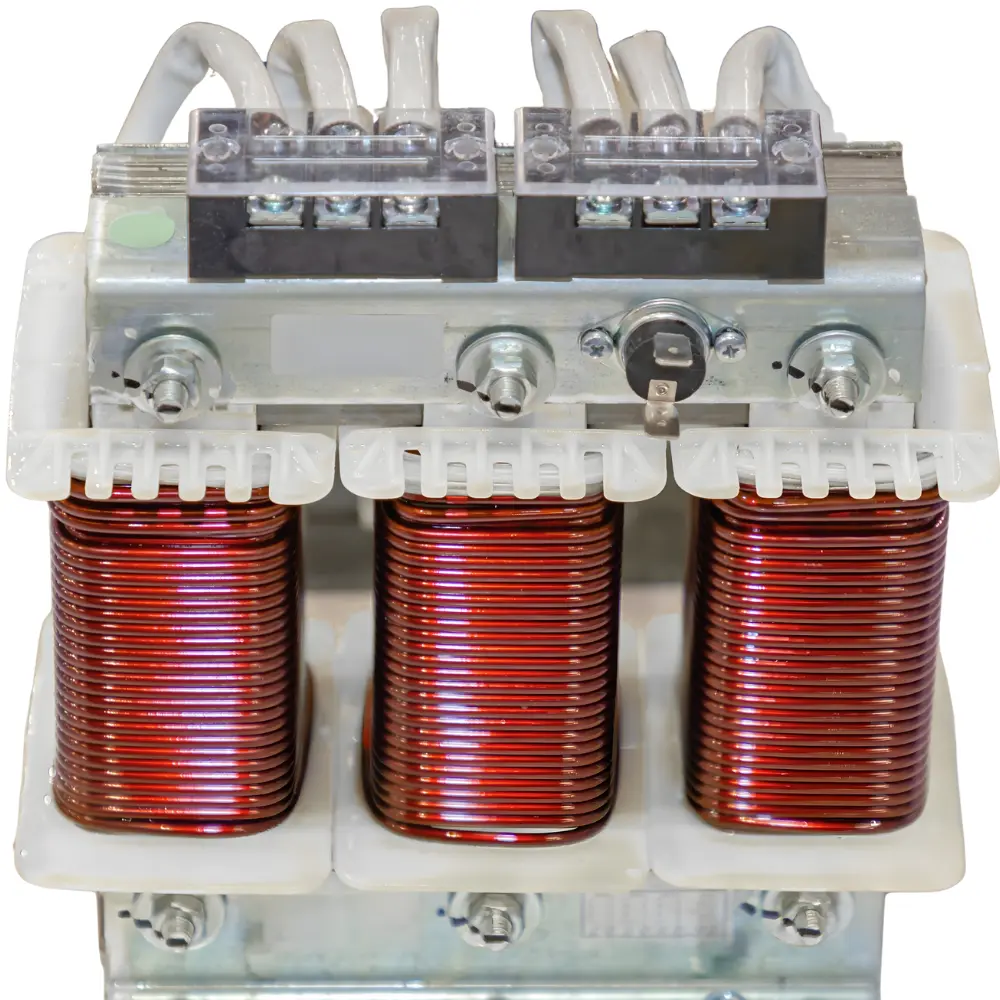

dv/dt Filters

A dv/dt filter is fitted on the output of a VFD/inverter to slow the voltage rise (dv/dt) of PWM pulses.

| Specifications | |

| Voltage Rating | 3PH - 400V to 690 |

| Max. Peak Voltage | <1000V |

| Typical dv/dt reduction | Factor 8 to 12 |

| Current Rating | 12 to 1100A |

| Voltage drop | <3V |

| Insulation Class |

F Class for dry type (H Class on request)

|

| Overload Capacity | 1.5× rated current for 1minute |

| Cooling | AN/AF |

| Motor Frequency | 0 to 60Hz (Up to 400Hz on request) |

| Applicable Standards | IEC 60076-6 (power reactors): temperature rise, dielectric, routine/type tests. |

| Certifications | CE ROHS |

- Essential for Long motor cables (tens–hundreds of meters) to limit surge/reflection at motor terminals

- To Protect motor insulation (PD risk) on older/reused or non-inverter-duty motors

- To reduce common-mode stress/shaft voltage when no sinusoidal output is needed

- Helps quick retrofit on existing VFDs where space/cost are tight (smaller than sine filters)

- Essential to meet basic OEM/utility dV/dt limits without full harmonic attenuation

- Helps lower EMI/RFI emissions enough for nearby instrumentation compliance

- Essential for marine/OEM skids with mixed cable types and unknown terminations

- Helps lower acoustic noise from PWM edge “buzz” in motors/piping

dV/dt Filters — Sizing Notes (Quick Guide)

- Purpose: Limit PWM edge steepness at the motor terminals to reduce insulation stress, ringing, and EMI.

- When to use: Cable lengths from ~25 m to 300 m+, older/non-inverter-duty motors, sensitive environments.

- Inputs needed: VFD VLL, motor current, cable length & type, carrier kHz, acceptable dV/dt at motor (e.g., ≤ 1–2 kV/µs).

How to size (rules of thumb)

-

Inductance target (LV drives): choose reactor so fundamental reactance ≈ 3–5% at 50/60 Hz per phase.

L≈XL2πf=(0.03 − 0.05) Vϕ/Irated2πfL \approx \dfrac{X_L}{2\pi f} = \dfrac{(0.03\!-\!0.05)\,V_\phi/I_\text{rated}}{2\pi f}L≈2πfXL=2πf(0.03−0.05)Vϕ/Irated - Carrier attenuation: aim for >50% reduction of edge rate at the motor; increase L for very long cables or high carrier (>6–8 kHz).

- Core choice: Gapped laminated core (most LV/MV) or air-core (zero saturation, larger size). Always gap iron cores for linearity.

- Thermal/derating: rate for RMS with harmonics (crest factor 1.8–2.2 typical). Check hot-spot at 40–50 °C ambient.

- Voltage drop impact: 3–5% X at fundamental → small efficiency hit; verify motor starting margin.

- Common-mode (optional): add a CM choke if bearing currents/EMI are concerns.

Spec line (example)

- “dV/dt Output Reactor, 415 V, 75 A, 5% X @ 50 Hz, 0.55 mH/phase, Class F, gapped iron-core, ΔT ≤ 80 K, audible noise ≤ 65 dB, designed for motor lead 150 m, carrier 4 kHz, dV/dt ≤ 1.5 kV/µs at motor.”

Installation Notes

- Place filter near the VFD (default). For very long runs, evaluate locating near the motor (case by case).

- Keep lead dress short & symmetrical; bond enclosure well to reduce EMI.

- Verify inverter carrier and min. load settings recommended by the filter vendor.

- Check temperature rise after first run (thermal imaging); re-tighten terminations.