Read time: ~4 minutes

Executive summary

Higher-order PWM harmonics from VFDs raise winding temperature, stress insulation, and cause bearing EDM—quietly shortening motor life. Risk jumps with high switching frequency, long motor leads, poor grounding, and non-inverter-duty motors. A simple stack—filters, proper cable/terminations, shaft grounding, and spec discipline—restores reliability fast.

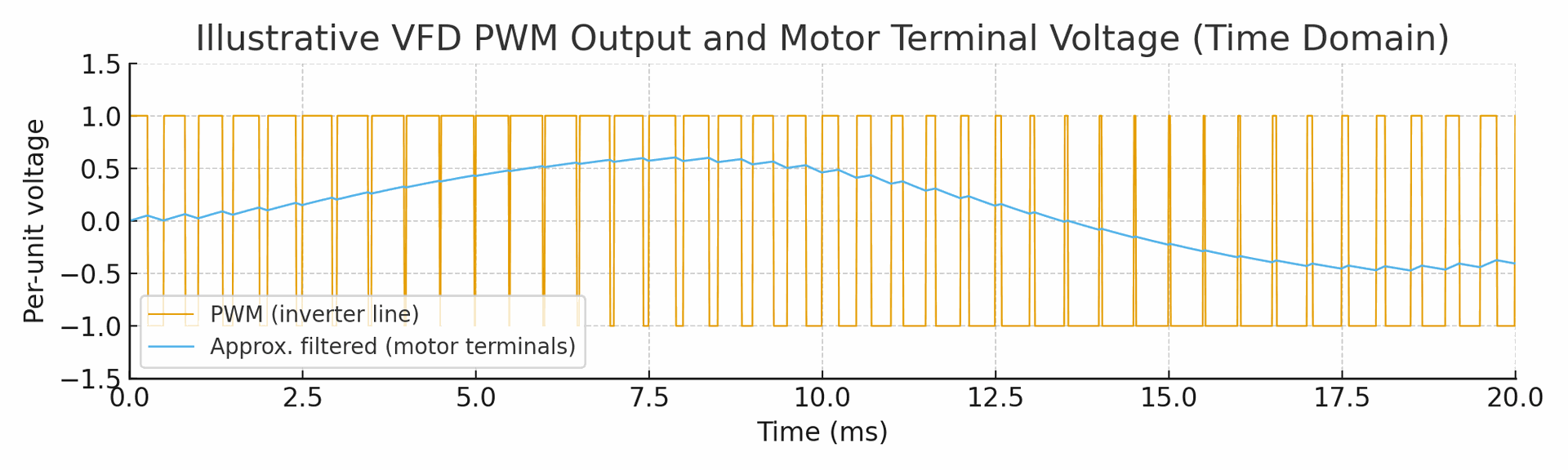

What’s on a VFD output (and why it matters)

A VFD synthesizes a sine via high-frequency switching. Besides the fundamental, you get:

- Higher-order components (carrier + sidebands)

-

Fast dv/dt edges that reflect on long cables

These create extra heating, torque ripple, over-voltage at terminals, and common-mode currents.

Where harmonics hurt motors

- Thermal: I²R at harmonic freq + iron/stray losses → hotter windings → faster insulation aging.

- Mechanical: Voltage harmonics → torque pulsations → vibration/noise and fatigue.

- Insulation: High dv/dt + long leads → spikes and partial discharge risk.

- Bearings: Common-mode voltage drives shaft currents → EDM fluting and grease breakdown.

When problems spike

- High switching frequency (set “high” by habit)

- Long motor leads or multiple motors per drive

- Asymmetric/loose EMC terminations, poor earthing paths

- Motors not rated “inverter-duty”

Measure first (acceptance checklist)

- THDi at the input measures the quality of power the VFD draws from the utility grid (relevant to utility compliance).

- THDu at the output measures the distortion/spikes the motor is exposed to (relevant to motor health).

- Shaft/common-mode voltage (peak, repetitive)

-

Winding temperature rise, vibration (mm/s)

Capture a commissioning baseline and trend quarterly.

Fix what matters (mitigation ladder)

- Specify right hardware: Inverter-duty motor (IEC 60034-17/-25; NEMA MG1 Pt 31).

- Tune the drive: Use sensible switching frequency; for long leads, don’t default to max.

- Condition the output: Output reactor → dv/dt filter → sine filter (pick by lead length/risk).

- Cable & terminations: EMC-rated cable, 360° glands both ends, symmetrical grounds.

- Bearing protection: Shaft grounding ring (DE) + insulated NDE bearing.

- Earthing/bonding: Low-impedance PE back to the VFD, avoid daisy-chain earths.

- Verify: Re-measure THDu, shaft V, temp, vibration.

30-day action plan

Week 1: List top VFD-driven motors; measure THDu, shaft V, temps, vibration; note cable lengths/grounding.

Week 2: Lower switching freq where safe; add output reactors on noisy feeders; fix EMC terminations/PE paths.

Week 3: Add shaft grounding + insulated NDE bearing; for long leads, add dv/dt or sine filter.

Week 4: Re-measure, compare to baseline; set quarterly trending.

Business impact

By cutting thermal stress and bearing EDM, you extend MTBF, reduce change-outs, and stabilize uptime. On critical assets, payback for filters + bearing kits is commonly within a year through avoided failures and downtime.

CTA: Want this tailored to a specific line (pump, fan, compressor, spindle)? Share motor kW, cable length, switching freq, and any bearing/temperature issues—I’ll return a one-page, phased fix list.

Author: Mahesh A. Toraskar